Recent searches

Search options

@Stormgren Wrt number 9, I used a Fluke 1503 to hi-pot test my entire cable plant to 1 kV when I rewired my house.

Found two instances where a wire had its insulation nicked on the sharp edge of a fitting as I was pushing the cable into the junction box. The first was a dead short and would have blown a breaker instantly, but the second only started arcing at 300V and would probably have resulted in intermittent breaker trips that would have been a nightmare to find, to say nothing of repairing once the walls were put in over it.

@Stormgren And flux residue... I have some fun stories there too. I generally leave no-clean flux residue on a board after reflow soldering unless it's a super sensitive application, but I try to clean stuff as much as I can after hand soldering.

Some years ago I was asked to help debug a crystal oscillator on a friend's project. I tried tweaking the load capacitance slightly and after soldering the new caps in, it seemed to work so I scrubbed off all the flux, tested again, and... it didn't work.

After a bunch of investigation, we realized that the MCU in question did not include a feedback resistor from XI to XO and required a few megohms of external resistance. The incompletely cooked flux residue after hand soldering was conductive enough to provide this feedback path until cleaned.

Bodged a 1M 0402 across it, defluxed, and it still worked!

@Stormgren Another time I encountered a batch of test fixtures from a big name T&M vendor that hadn't been properly defluxed after soldering.

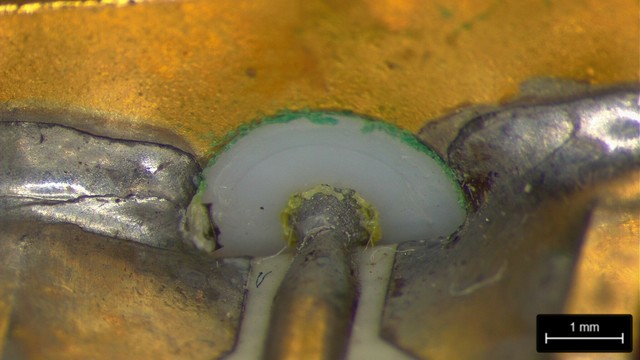

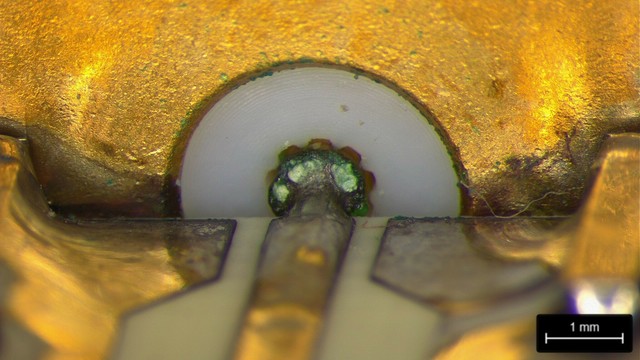

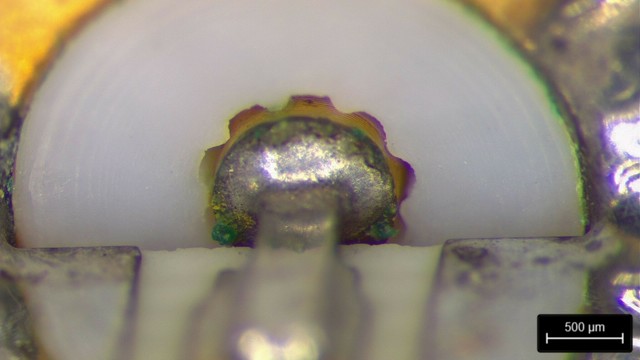

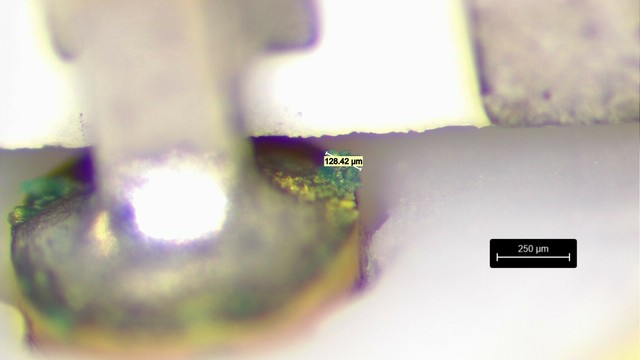

They all had visible corrosion right around the insulator of the SMA connectors (of only one gender - i can't remember which but the board was a thru configuration with both and only one was impacted, consistently).

There was no visible stickiness or flux residue but I strongly suspected this was flux corrosion given the location (in and around difficult-to-clean areas flux might have wicked into). I RMA'd all of them and the vendor confirmed this appeared to be due to flux, introduced a more aggressive cleaning process, and sent me a bunch of free replacements which so far haven't shown any signs of corrosion.